Micropol-System

... the method for producing high-grade, individual earmoulds.

Our pressure polymerisation flasks Micropol 2000, Micropol 3000, Micropol 100 and Minipol 100 are manufactured of high-grade special steel and hard-chrome plated.

Micropol 2000 | Micropol 3000 | Micropol 100 |

|  |  |

What makes the Micropol-system different from conventional earmould production methods?

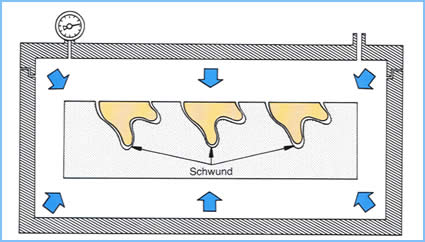

The resins used in earmould production tend to shrink during the curing process. This shrinkage is dependent on the moulding pressure used. The result is that earmoulds, produced using conventional techniques, tend to turn out smaller than the impression.

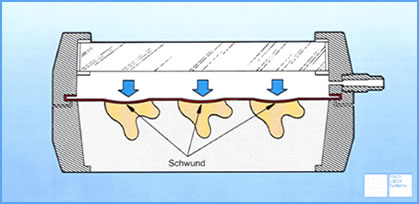

Using our Micropol-system it is possible to produce top quality earmoulds with an extremely high fitting accuracy. The pressure polymerisation flask Micropol 2000 is made up of a pressure chamber section and a ring section which retains the plaster mould.

Using a membrane, the resin is forced into the plaster mould from the pressure chamber at an extremely high pressure of 7 bars. As the plaster is permeable to air, no conterpressure is able to build up in the mould.

Instead, the resin is pressed flush against the plaster walls by the pressure of the membrane. The shrinkage arising during the polymerisation process thus only occurs at the part of the mould which subsequently undergoes further treatment. The unusally high moulding pressure of 7 bars creates the high homogeneity of the resins which produces excellent physical and chemical properties.